Sautter Lift Components’ SG Series provides a high-quality range of small, compact safety gears. Ideal for narrow shafts and new installation, they allow optimum use of space in the lift car, requiring only 19.5mm (with 4mm clearance) between the guide rail head and the safety gear frame.

The SG1D-1 safety gear provides catch downwards performance only and is often used for new catch frames, when catch upwards is covered by a brake on the lift drive.

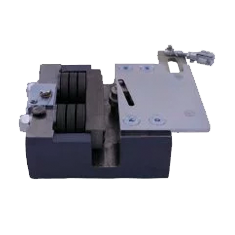

Break Safety Gear SG1D-1

Catch In Downward Direction

Max. Nominal speed: 2.50 – 2.80 m / s

Max. Release speed: 3.23 m / s

Minimum tread width: 19mm

Railhead thickness: 5-16mm

Safety gear (downward)

Total mass [kg], min. – Max.

Machined rails,

– dry: 543 kg – 3,095 kg

– oiled: 523 kg – 2,935 kg

Drawn rails,

– dry: 305 kg – 2,605 kg

– oiled: 299 kg – 2,542 kg

The brake safety device SG1D-1 is very compact, as standard it is available with two different release rods.

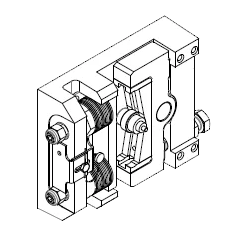

Break Safety Gear SG2D-1

Catch In Downward Direction

Protective device against overspeed (upwards) and unintentional car movements

Max. nominal speed: 2.50 – 2.80 m/s

Max. release speed: 3.23 m/s

Minimum track width: 19mm

Railhead thickness: 5-16mm

Safety gear (downward)

Total mass: 292kg (min) – 2.889kg (max)

(depending on rail type)

Overspeed (upwards)

Braking force: 4.001 N (min) – 45.353 N (max)

(depending on rail type)

Unintentional car movements (UCM / A3)

Max. Release speed: 2.20 m/s

Braking force: 4,001 N (min) – 45,353 N (max)

(depending on rail type)

SG2D-1, Version 1

The braking force for catching downwards and upwards can be set continuously and independently with variant 1.

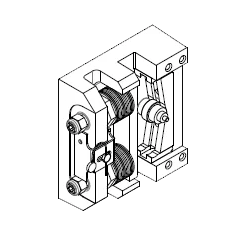

SG2D-1, Variant 2

Variant 2 of the SG2D-1 is more compact. The ratio for the braking forces below / above is fixed.

Advantages of the SG Safety Gears Series

- Small, compact design

– 140mm x 146mm x 49.5mm for the SG1D-1

– 200mm x 164mm x 56.5mm for the SG2D-1 - High catch load combined with high speeds

- Minimum space required between guide rail head and frame attachment: 19.5 mm (4 mm air)

- Uniform deceleration due to long spring travel of the disk springs

- Flexible use in systems with internal and external guide rails (MRL, backpack)

- Low forces for releasing the car from the catch

- A wide range of options for triggering the safety gear enables optimum synchronization, matched to different car designs

- Prevention of unintentional release by separate securing of the catch roller

- Safety gear is type-tested without release, this allows flexible installation